Contact us

Factory:, Village 6, Dong Son, Thuy Nguyen, Hai Phong.

Hanoi Office: G1 Buidling, Vinhome Green Bay, Me Tri, Nam Tu Liem, Ha Noi.

Fax: (84)-02253 574 566

Cleanroom Equipments

CLEAN ROOM EQUIPMENT

Surely each of us has ever seen the image of engineers, employees or workers of some factories wearing tight clothes, hats, masks, gloves while working. . Those are mandatory possessions when they work in a clean room. So what is a "clean room"?

CLEAN ROOM EQUIPMENT

I. What is clean room equipment?

Put simply, "clean room" is a very clean room. According to ISO 14644-1, it is a room where the concentration of suspended particles in the air is controlled and minimized, in addition Other factors in the room such as temperature, humidity, pressure can be controlled and controlled.

A clean room is usually a closed room, in which the amount of dust in the air is kept to a minimum, in order to prevent contamination of the research, manufacturing and manufacturing processes. At the same time, the temperature, pressure and humidity of the air are controlled and controlled to best benefit these processes. In addition, the room is guaranteed aseptic, free of harmful gases in its "clean" sense.

Clean room equipment

Clean rooms have become an indispensable part for factories in developed countries. In Vietnam, this is a new concept, but there are many factories building clean rooms to meet the strict standards of products of business partners in European and American markets ...

In the next few years, clean room is a mandatory construction code for many factories, hospitals ... to ensure a safe environment for producing products for consumers, and to ensure safety for consumers. patient.

II. The common clean room equipment

2.1 Clean room equipment

The common clean room equipment:

- Dust blower (Airshower)

- Product transfer box (Pass box)

- Clean table (cleanbench)

- FFU (Fan filter Unit)

- Static field meter.

- Particle counter (Particle counter)

- Air velocity meter (Air velcro counter)

- Types of air filter, HEPA clean room filter, ULPA (clean room filter, HEPA filter, ULPA filter)

- Types of clean room gauges, clean room inspection, electrostatic measurement to manage pollution, prevent contamination (contamination control)

Clean room equipment commonly used

2.2. Clean room appliances.

- Clean room table, antistatic, clean room chair (esd chair, clean room bench)

- Anti-static tray, anti-static container (anti static tray, box)

- Antistatic rack (antistatic rack)

- Anti-static curtain

2.3. Personal equipment

- Clean room clothes, clean room clothes (Clean room garments, clean room suit)

- Clean room shoes cover

- Clean room mask

- Clean room cap, clean room cap (clean room cap, clean room head cover)

- clean room gloves, clean room gloves (clean room gloves)

2.4. Consumables

- Sticky mat (Sticky mat)

- Rubber sheet

- Cotton swabs (Cotton swab)

- Clean paper wipes, clean room wiper

- Writing clean rooms, clean room paper (clean room pen, clean room paper)

Clean room equipment commonly used

III. The importance of clean room equipment

Clean room equipment, utensils and utensils are a huge factor that directly affects the quality of clean rooms in research as well as production. Can include the name of equipment such as clothing, hats, masks, glasses, gloves, thick, sandals, writing paper, manipulation tools, tables, chairs, ... If not the right choice Standard products for clean rooms are very likely to have serious consequences on the product.

IV. The need for a clean room

Companies producing and assembling electronic components and circuit boards often encounter problems of product failure due to the presence of dust particles in the air, so clean rooms are especially focused on dust-free. Since then, replicated systems have developed, control systems, filtration systems, and accordingly protective clothing products to prevent room dust and dirt.

Today, clean rooms are used for many fields such as medical, material science and technology, electronic components, physics, chemistry, biology, precision engineering, pharmacy, food, semiconductors...

V. Standard clean room

The first standard of a clean room is the content of dust, that is, the content of dust particles suspended in the air is controlled. If we compare it figuratively, the diameter of a human hair is about 100um, the dust in the room can be from 0.5 to 50um in diameter.

5.1 An important international standard for clean rooms

· US Federal Std 209E 1992

· EEC cGMP 1989

· France AFNOR 1989

· German VDI 2083 1990

· British BS 5295 1989

· Japan JIS B 9920 1989

· ISO EN 14611-1 1999

· Australia AS 1386 - 1989

Clean room standards were first introduced in 1963 in the United States, and have now become common standards for the world. These are standards that specify the amount of particulate matter per unit volume of air. It is divided into levels of dust size and type of room determined by the number of particles larger than 0.5 um in a volume of 1 cubic foot of air in the room.

5.2. Federal Standard 209 Standard, 1963

This standard was first defined in 1963 as 209 and then continuously improved, perfecting versions 209A, 209B until 209E.

Federal Standard 209 Standard, 1963

5.3. Federal Standard 209 E standard in 1992

This standard defines the content of suspended dust in air in standard cubic meters. The clean room classification is determined on a log scale of dust content with a diameter greater than 0.5 / mum.

Federal Standard 209 E standard in 1992

5.4. ISO 14644-1 standard

The International Standards Organization has set standards for clean rooms of international standards. The ISO 14644-1 standard, released in 1999, is called "Air Cleanness Classification".

ISO 14644-1 standard

In particular, the level of air pollution in the room depends on the dust particles generated in the room activities, not just the fixed number in the room. Therefore, in room standards always require continuous cleaning systems, which specify the number of people and activities that are allowed to be performed in the room.

There are also different regulations on the peculiarities and characteristics of each industry.

For the electronics industry in Vietnam, clean room is still a new concept and has not been widely applied. However, in fact today, there are many factories building clean rooms to meet the strict standards of products for business partners in the markets of Japan, Korea, China, USA and other countries. in Europe ...

VI. Application of clean room

6.1 Application of clean room for food storage

Foods such as cakes, candies, canned foods, dried foods or fresh foods must be stored in a clean and safe space. Because if the amount of microorganisms is high and the dust content is high, it will cause the food to be contaminated, affecting the fermentation process, leading to faster spoilage. Therefore, preserving food is a closed process, in order to limit the development of microbiological processes to increase the shelf life of food.

At the same time, during the production process, the clean room ensures safer food, free from harmful agents, resulting in unsatisfactory production or unqualified product quality. Therefore, many businesses and companies now apply clean rooms to ensure better preserved food.

6.2 Application of clean rooms in cosmetic production

Cosmetics are an indispensable item in life today, more than the need for beauty, skin care of people is increasingly focused. Therefore, to make quality and safe beauty products, it must be produced in a clean, standard environment. Because bacterial cosmetics are very easy to grow and cause allergies, backfire or damage to the skin, the application of clean rooms in cosmetic production and storage is essential. set.

Today, many factories and companies have applied clean rooms in cosmetic production, in order to provide customers and consumers with the most safe and quality beauty products. ResHPCos is a cosmetic processing factory that has applied clean rooms and received clean room construction for other large and small cosmetic companies and factories and has been certified by the Ministry of Health to meet international standards. For more information, you can contact reshpcos.com immediately.

6.3 Application of clean room in Health

The health sector is a key industry, the first priority needs clean room application. Because this is an important environment, it is necessary to have advanced and scientific equipment to support medical examination and treatment of patients. Clean rooms are used in operating rooms, isolated patient rooms or blood storage rooms, medicines, vaxins ... to ensure patients are not affected by outside agents, even if only a small dust particle.

In particular, clean rooms are applied in the manufacturing process of drug production research. When manufacturing drugs and medical devices, the top task is to protect these products from bacteria, harmful agents, to ensure the best quality of medicines and medical equipment. maximally cause complications and danger to patients because of infection when using. Therefore, the application of clean room to health is a condition not to be missed.

Application of clean room

6.4 Application of clean rooms in electronics industrialization

In electronics manufacturing, especially in the industrialization of electronics, ICs, semiconductors, chips ... require high safety, because only a small dust particle will fall into the process of damaging the production process. . Therefore, in the electronics industry, it is imperative to use clean rooms, clean rooms to ensure the most rigorous standards, such as absolute dust resistance, stability of temperature, humidity, pressure and ability. Antistatic support is a great help in the electricity production process.

And you can some companies like Sharp, Samsung, LG, Toshiba ... produce electronic appliances, all of them are equipped with labor protection equipment for employees very carefully and require to do in a clean room environment to not Any dust attached to the board causes deterioration and damage.

6.5 Application of clean room in research science

Engineers, scientists or research experts in the field of science and chemicals are required to study in a clean room. Because in the process of research, requires meticulous, accurate so they need a clean space, ensuring the amount of dust or bacterial level in the room is minimal. A standard clean environment will help the research and testing process get the most accurate results. And clean rooms are often used in laboratories such as: research and manufacture of drugs, vaccines, experiments in the field of biology, chemistry ...

6.6 Application of clean rooms in agriculture

In order to create good plant varieties, with advantages and productivity superior to traditional varieties, scientists must conduct experimental cultivation of clean room microorganisms, after completion will create new varieties. will be stored absolutely in a clean room that is stable and free from other organisms. To control the amount of microorganisms in the plant breeding and tissue culture centers of all kinds, Interior space plants meet the standards of the clean room, thereby making the process of caring and raising microorganisms safer and more effective.

Automatic Air Shower BT-ASA

Application

Automatic Air Shower is used in electronics, microelectronics, precision electronics, biological manufacturing industry, pharmaceutical industry,food processing ITO mode liquid crystal, printed circuit board surface mount technology manufacturing industry, aerospace, automobile manufacturing industry, dust-free painting industry, etc.

Infrared automatic door system

The most convenient feature of the automatic door system is the removal...

Automatic Roller Door - Sliding Door Cargo Air Shower Room BT-ASAR

Smart control chip

Double electronic interlock is to prevent cross-infection and to achieve sealing requirement.Built-in shutter door control chip can open automatically. Moreover, other conveniences like the infrared probe, transparent window, infrared induction blowing, clear indicartor light, emergency stop switch.

Modular design

the modular design makes the process of disassenbling become easier. At...

Circumfluent HEPA Box BT-HBC

The original design of diffuser

Diffuser design of the positive and negative alters concentric circle expansion, so that, the air flow in the form of round table supplies the air to clean room. Mereover, it can maximizedly sweep away the indoor dust with an even airflow. At same condition, it can...

Clean Booth BT-CB

Highly cost-saving

Bao Tien has changes the traditional design of clean booth. Mini clean unit takes the concept of modular integration design; this architecture is similar to SMIF form. It has a wide range of independent clean area. The only difference is that the transmission isnot carried aout by the connecting...

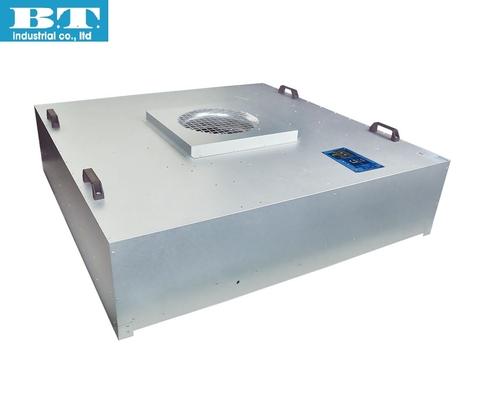

DC Fan Filter Unit BT-FFUDC

Intelligent control system

Using remote automatic control system and intelligent control is to gain a perfect match between mechanical components and electronic control system.

Simple warm-up and stop

Because 5 or more fans are connected, we can start a lot of fans are connected, we can start a lot of fans at the...

DOP HEPA Box BT-HBDOP

Good sealing

The DOP HEPA Box adopts the gel seal HEPA filter for better sealing.

High quality plate

The cabinet is made from the cold rolled steel with powder coated or stainless steel.

Excellent designed diffuser plate

Based on the principle of aerodynamics, designers carefully design the diffuser plate to ensure that the air jet...

DOP Laminar Flow Hood BT-DOPLFH

Good sealing

DOP Laminar Flow Hood equipped with gel seal ULPA filter makes sure good sealing.

Small calorific amount

Small amount of calorific value means you can reduce the calorific value of working area.

High air velocity

Laminar Flow Hood is a ceiling unit with motor inside, it is used for turbulent and laminar flow...

Embebed Pass Box BT-PBE

Quality selection

It's adpopted the polish stainless steel inside, which is flat neat and wearable. The surface material of pass box is cold rolled steel or stainless steel.

Good sealing

Doors in two sides with mechanical or electronic interlock device make them cannot be opened at the same time.

Good looking

Although it has simple...

General Air Shower BT-ASG

Smart control chip is applied widely

Intelligent programmable control, two-door electronic interlock, infrared sensor blowing, Air shower clear indicator, emergency stop button de,pnstrate stronger professional, convenience and security.

Energy saving

Due LED electronic lighting that consumes less electricity and high-efficiency energy-saving fan, it means that this air shower wastes less energy

Reasonable design

The air blows...

General Pass Box BT-PBG

Core value

Pass box has the function of air valve to prevent high pressure from spreading into the clean room. In addition, It can reduce operating personnel's movement, to make sure that dust cannot be brought into clean room and help keep the stability of the clean room.

Interlocking double door system

Mechanical...

HEPA Box BT-HB

Air distribution is more reasonable

The HEPA Box onjoys the most cutting-edge technogy from Japan, which makes the process of airflow distribution more reason-able. Moreover, The HEPA Box is also a terminal purifyling device for the class 1,000-300,000 Clean room and is the key equipment for clean environment.

High quality plate

The cabinet...

Integration Vertical Flow Clean Bench BT-CBIVF

Less shaking

Integration Vertical Flow Clean Bench. The combination of vertical unidirectional airflow, the low noise centrifugal fan, the plenum chamber, HEPA filter makes the operation less vibrant.

Low noise and free maintenance

High-quality fan applied to make sure low noise, free maintenance and easy operation.

Corrosion protection material

The cabinet is made from cold rolled...